Merus® A2 – Active Harmonic Filter

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

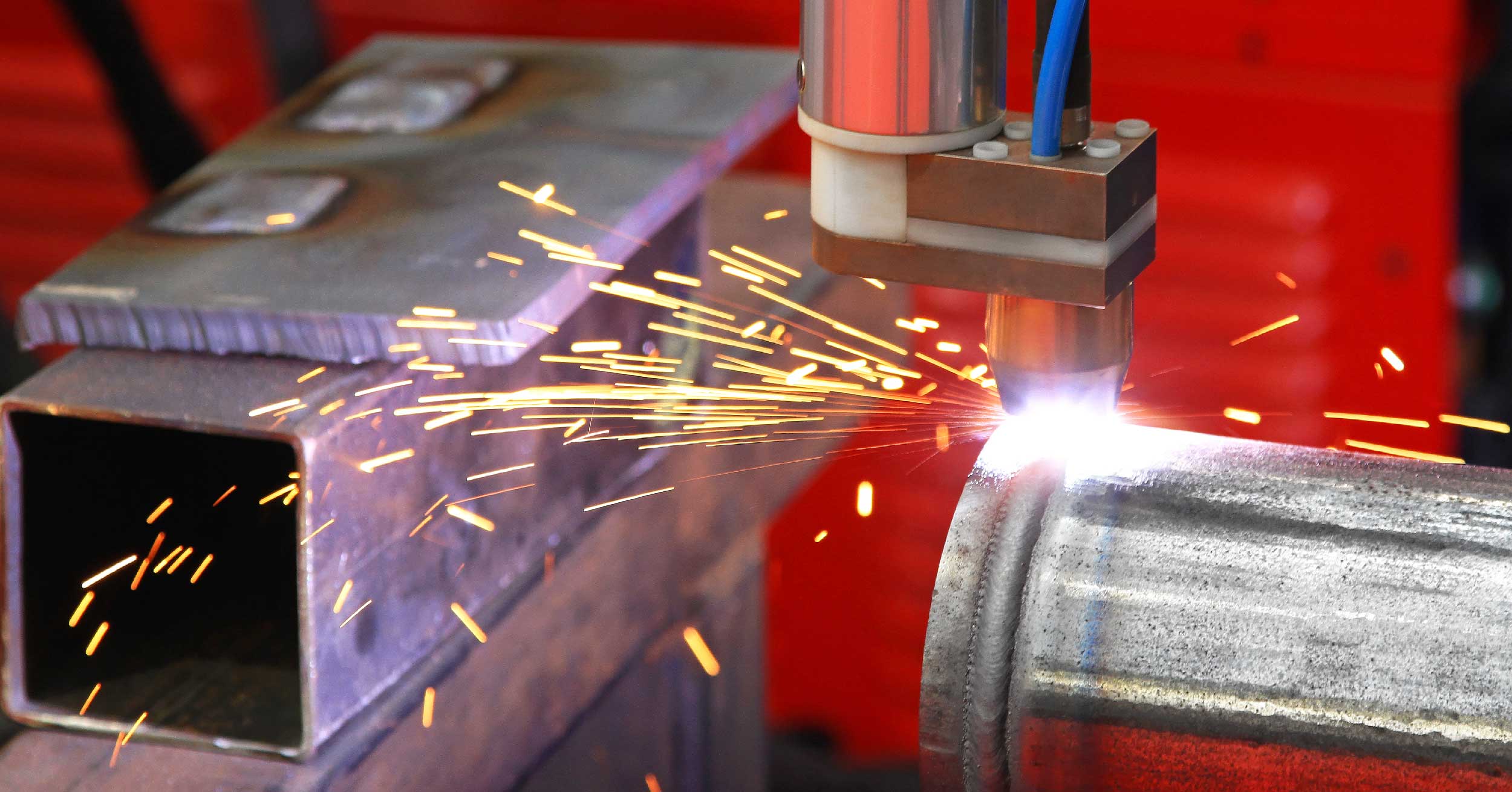

Automatic welding uses electric tools and equipment to control welding applications. Welding automation technologies are becoming more efficient and affordable by the day. Naturally, they have been increasing in numbers as they provide significant efficiency and flexibility advantages. Regrettably, welding machines are prone to poor power quality issues due to their nonlinear nature. Power quality has a serious impact on welding quality and consistency as well as productivity and efficiency. Welding applications may face voltage variations, flicker, and load unbalancing issues. Voltage variations and flicker can even disturb other facilities connected to the same bus bar.

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

Merus® HPQ is an all-in-one power quality system for combined active harmonic mitigation and power factor correction.